Flexible link chain for the sealing of wall penetrations

for gas, water, sewage pipes and cables

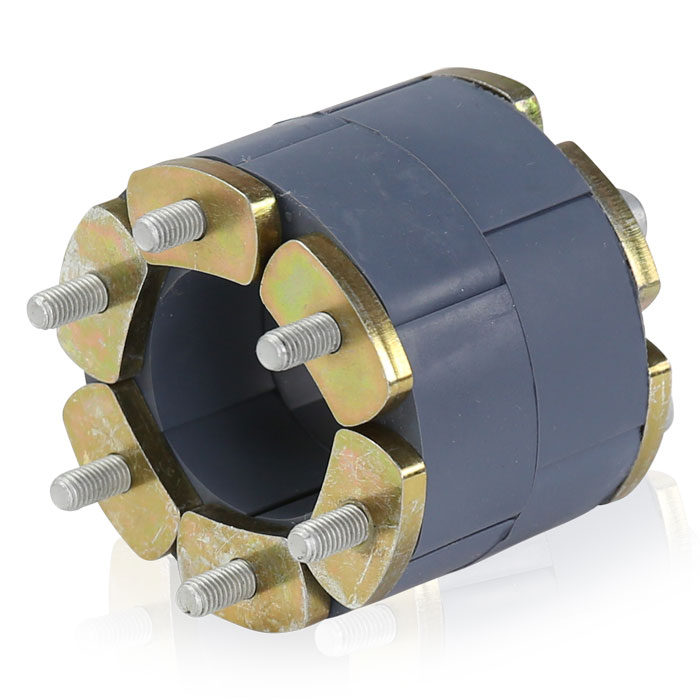

ORIGINAL LINK-SEAL®

Modular Seal

Type selection

LINK-SEAL® C - galvanized

LINK-SEAL® S 316 - stainless steel

Fields of application

Use in normal atmosphere, water or humidity. Suitable for electrical isolation and cathodic corrosion protection.

S 316: Resistant to water and against most inorganic (acids and alkalis) and organic substances

Material

EPDM-Rubber; bolts: C galvanized / S 316 A 4-70 stainless steel;

Shore A 50° ±5; pressure plates glass fiber reinforced polyamide

Properties

Temperature range -40 °C to 80 °C; pressure tight up to 5 bar;

electrical isolation with a dielectric strength of 500 V/mm

Sizes

LS 200 to LS 650

LINK-SEAL® BC - galvanized

LINK-SEAL® BS 316 - stainless steel

Fields of application

Particularly soft rubber, especially suitable for plastic pipes. Use in normal atmosphere, water or humidity. Suitable for electrical isolation and cathodic corrosion protection.

S 316: Resistant to water and against most inorganic (acids and alkalis) and organic substances.

Material

EPDM-Rubber; bolts: BC galvanized / BS 316 A 4-70 stainless steel;

Shore A 40° ±5; pressure plates glass ber reinforced polyamide

Properties

Temperature range -40 °C to 80 °C; pressure tight up to 3 bar;

electrical isolation with a dialectric strength of 500 V/mm

Sizes

LS 200 to LS 700

LINK-SEAL® OS 316 - stainless steel

Fields of application

Good resistance against oils; aromatic fuels; solvents; mineral oil-based products

Material

NITRIL-Rubber; bolts: A 4-70 stainless steel;

Shore A 50° ±5; pressure plates glass ber reinforced polyamide

Properties

Temperature range -40 °C to 70 °C; pressure-tight up to 5 bar; not UV resistant;

electrical isolation with a dielectric strength of 500 V/mm

Sizes

LS 200 to LS 650

LINK-SEAL® W - stainless steel

Fields of application

Suitable for applications in the drinking water sector

Material

EPDM-Rubber; bolts: A 4-70 stainless steel;

Shore A 50° ±5; pressure plates glass fiber reinforced polyamide

Properties

Temperature range -40 °C to 80 °C; UV-resistant; Radon tight; pressure-tight up to 5 bar; electrical isolation with a dielectric strength of 500 V/mm

Sizes

LS 200 to LS 650

LINK-SEAL® T - galvanized

Fields of application

Especially suitable for extreme temperatures

Material

Silicone-Rubber; bolts galvanized;

Shore A 50° ±5; pressure plates S235JR galvanized

Properties

Temperature range -55 °C to 163 °C (temporary up to 204 °C);

pressure-tight up to 5 bar; no isolating properties

Sizes

LS 200-T to LS 575-T

LINK-SEAL® KIT

Pre-assembled LINK-SEAL® rings for the most common pipe combinations as a craftsman's set.

LINK-SEAL® BC - galvanized

LINK-SEAL® BS 316 - stainless steel

Fields of application

Particularly soft rubber, especially suitable for plastic pipes. Use in normal atmosphere, water or humidity. Suitable for electrical isolation and cathodic corrosion protection.

S 316: Resistant to water and against most inorganic (acids and alkalis) and organic substances.

Material

EPDM-Rubber; bolts: BC galvanized / BS 316 A 4-70 stainless steel;

Shore A 40° ±5; pressure plates glass fiber reinforced polyamide

Properties

Temperature range -40 °C to 80 °C; pressure tight up to 3 bar;

electrical isolation with a dielectric strength of 500 V/mm

Sizes

Core drillings from 50 mm to 350 mm

Download

Product Information

Properties

- Easy and quick installation due to pre-assembled modules

- Different versions available for potable water, oil, fuel, solvents and high temperature resistance

- High quality rubber parts ensure long lifetime

- Protected position in the masonry

- Suitable for retrofitting

- Choice of galvanized 8.8 or stainless steel bolts A4-70

- Color differentiation of the various rubber qualities

- Electrically isolating

- Hydrostatic sealing against pressing water

Fields of application

- For sealing wall penetrations of gas, water, sewage pipes and cables (considering the calculation basis and the suitability of the product on site)

- Tank embeddings

- Casing pipe seals

Description

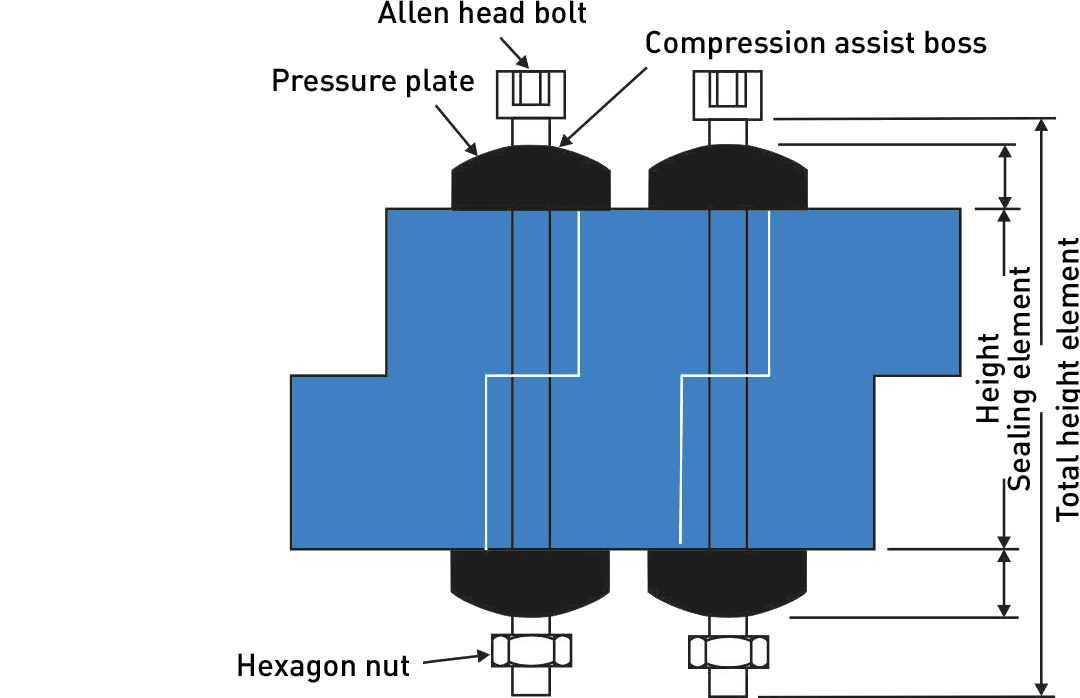

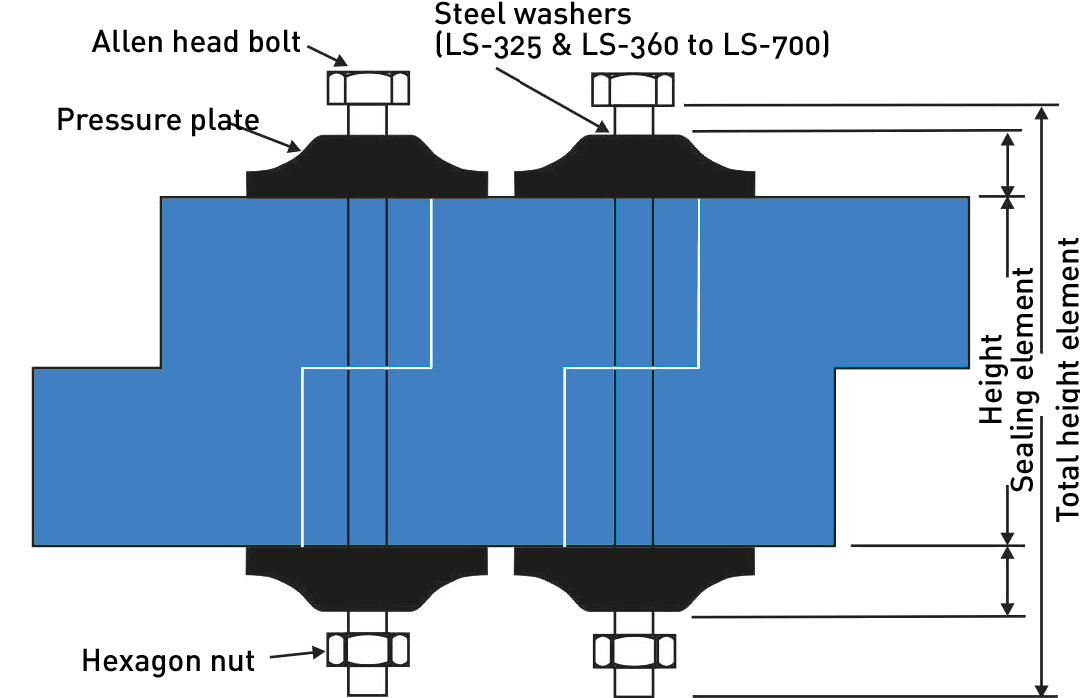

The radial expansion of the rubber parts ensures a permanent, pressure-tight and secure sealing of the annular space. For particularly thin-walled plastic pipes such as pre-insulated, flexible casing and corrugated pipe systems, a Compakt Temp or Compakt Super Soft is recommended.

Notes

- The surface of the core drilled holes should be coated to protect the reinforcement from corrosion. Therefore we recommend ProteX epoxy resin or ProteX sealant. The specified values for the pressure tightness are valid at 23 °C. For different, higher permanent operating temperatures, changing temperatures and permanent pressure, it might be necessary to fit an ejection safety device.

- Please be sure to ask us in advance about the technical feasibility of planned applications for which there is no description (e.g. applications in the biogas or food sector).

The purchaser bears the sole risk for use in Fields of application not described, we do not accept any guarantee for the suitability of the product.

Technical Information

Type selection

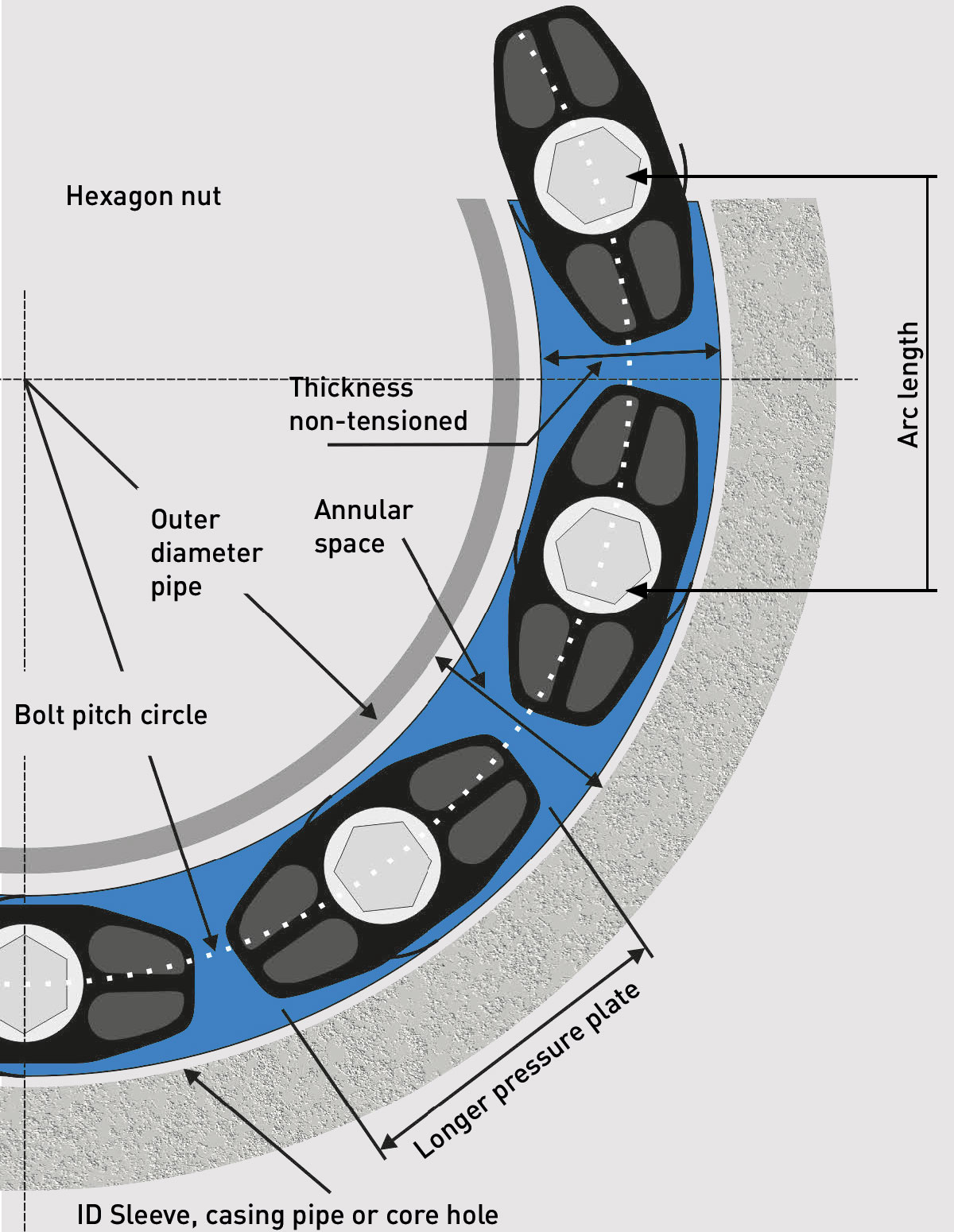

The suitable LINK-SEAL® for the application results from the thickness of the annular space between the casing pipe (wall sleeve) and carrier pipe. The perfect LINK-SEAL® is smaller than the annular space in a non-tensioned condition and larger in tensioned- condition.

To calculate the appropriate LINK-SEAL® annular space seal, use our online calculation program or the type selection as a basis for calculation. This is available for you to download online as a PDF.

Original LINK-SEAL® Modular Seal

Manhole sealing

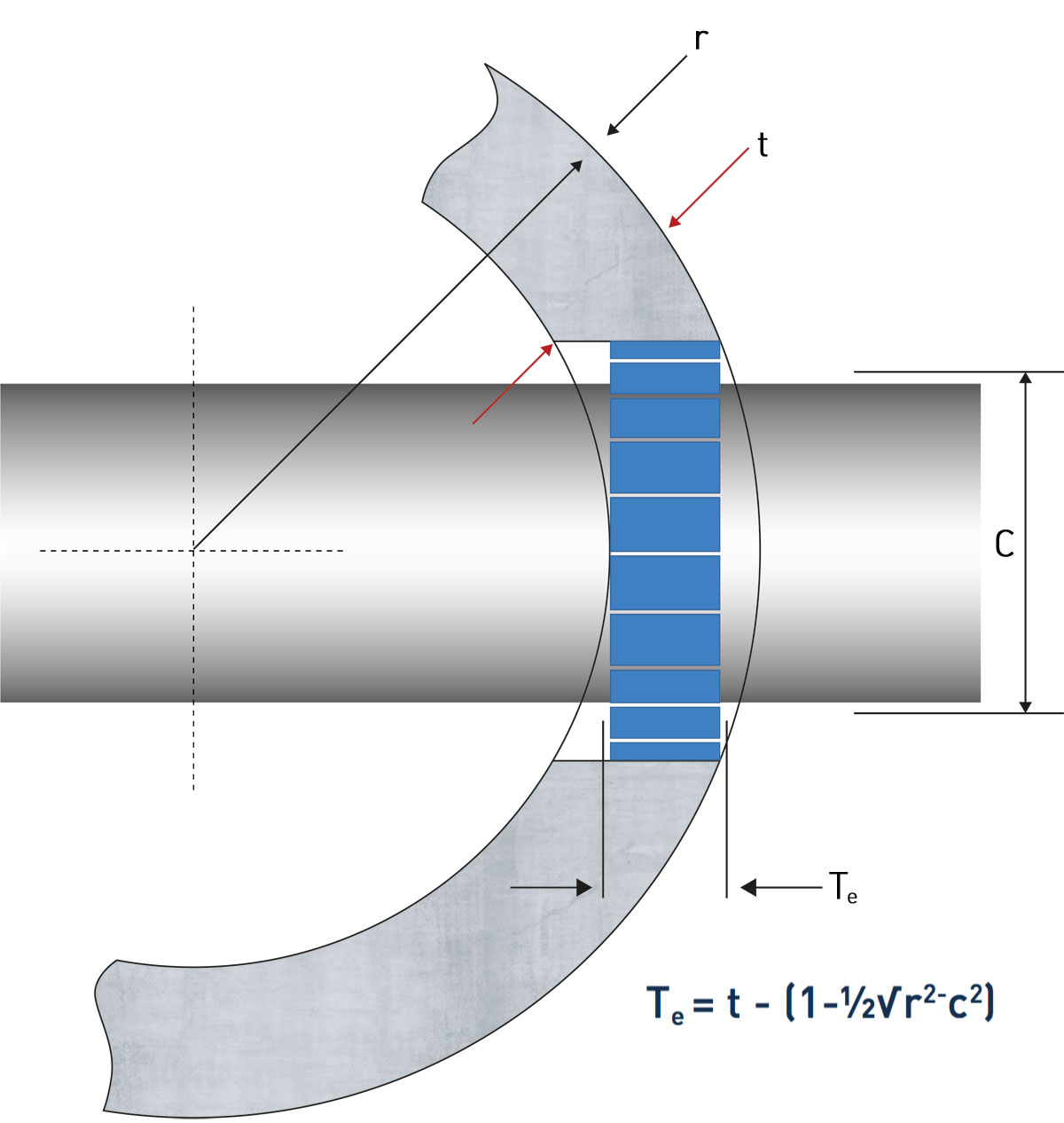

If LINK-SEAL® modular seals are used for a penetration in a curved wall (e.g. manhole sealing), it must first be checked beforehand whether a sufficiently large effective sealing surface (Te) is available.

The effective wall thickness can be determined by scale drawing or by using the following formula. It must be greater than or equal to the required minimum effective wall thickness of the selected LINK-SEAL® type.

| LINK-SEAL® | Type required Minimum wall thickness |

|---|---|

| LS 200 - LS 275 | 75 mm |

| LS 300 - LS 315 | 100 mm |

| LS 325 - LS 360 | 120 mm |

| LS 400 - LS 475 | 140 mm |

| LS 500 - LS 650 | 150 mm |

| LS 700 | 200 mm |

The determined effective sealing surface (Te) must be at least as large as the required minimum wall thickness for the selected LINK-SEAL® type. If the effective sealing surface (Te) is at least 40 mm (for core holes from Di 800 mm at least 80 mm), alternatively a Compakt seal can be selected.

Legend:

Te = Effective sealing surface available

t = Wall thickness

r = Outer diameter

c = Inner diameter core hole / opening

Suitable Accessories

Certificates

To offer our customers the best possible quality and service, we are organized according to DIN EN ISO 9001:2015 and have this continuously checked and certified.

CERTIFICATE ISO 9001:2015

This certification documents our conformity of the quality management system

AEO-CERTIFICATE

Authorized Economic Operator "AEOC (customs simplification)"

LINK-SEAL® MODULAR SEAL

- Lloyd‘s Register: “Pressure Test for Wall Penetration Seal, Type LINK-SEAL® Modular Seal”; Certificate No: APE 0409369/1

- TÜV certificate and reports:

- TÜV SÜD: Production facilities audit (annual)

- TÜV SÜD: Technical report DDA4/118/94 Component testing of a modular seal - FHRK quality seal: FHRK test specification GE 101 seals (test report no. G 30 322-6-2) Original LINK-SEAL® Annular space seal type C / type S316

Drinking water applications

- WRAS: Material approval

- ACS: Certificate of sanitary conformity

- Pressure plate testing: Material testing DVGW W270; KTW

- Sealing element: Material testing DVGW W270; UBA ELL

- Radon tight: Test report Dr. Joachim Kemski, Radon tight LINK-SEAL® W Sealing material