For quick and easy installation to

seal pipe and cable penetrations

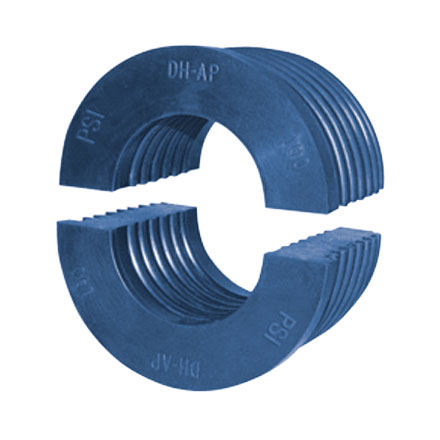

PlugiT

Sealing Plug

Type selection

PlugiT EPDM - black

Fields of application

Standard rubber for gas- and water-tight sealing (e.g. heating pipes and water pipes)

Material

EPDM-Rubber

Properties

Temperature range -25 °C / 110 °C; pressure-tight up to 3 bar

Sizes

Core drillings 40 to 200 mm

PlugiT Nitrile - blue

Fields of application

Good resistance to oils and greases (e.g. hydraulic systems)

Material

Nitrile

Properties

Temperature range -25 °C / 110 °C; pressure-tight up to 3 bar

Sizes

On request

PlugiT FS

Fields of application

Highly fire retardant rubber (e.g. fire retardant, gas- and waterproof sealing of pipes)

Material

FS

Properties

Temperature range -30 °C / +120 °C; pressure-tight up to 3 bar

Sizes

On request

PlugiT Silicone - brown

Fields of application

Resistant to high temperature differences (e.g. in cooling and steam pipes)

Material

Silicone

Properties

Temperature range -60 °C / +200 °C; pressure-tight up to 3 bar

Sizes

On request

PlugiT Viton - green

Fields of application

Resistant to chemicals (e.g. in laboratories)

Material

Viton

Properties

Temperature range -25 °C / 200 °C; pressure-tight up to 3 bar

Sizes

On request

Download

Product Information

Properties

- Horizontal and vertical installation

- Easy installation

- Wide range of applications

- Noise-absorbing

- Vibration-absorbing

- Electrically non-conductive

- High abrasion resistancet

Fields of application

- Sealing of pipe and cable penetrations which are led through walls and ceilings.

Description

No special tools are required for quick and easy installation; the sealing plug is simply hammered into the annular space. The profiled design of the plug ensures a pressure tightness against gas and water up to 3 bar. Relevant test certificates are available. The sealing plugs are made of high-quality rubber and are extremely abrasion-resistant. Various rubber qualities are available for the different fields of application in industry and construction.

Notes

- The plug can only be removed by hammering it out from the backside

- Core drillings or casing pipe dimensions must be checked for a tolerance of <1mm before installation

- Plug cannot be adjusted, a pipe support is mandatory

Technical Information

Use in a wall penetration

When using the seal in a core drilled hole which was made by means of a diamond drill bit, make sure that the surface is good and the concrete is of good quality.

The PlugiT sealing plug is driven from the outside of the wall into the annular space between the core hole and the carrier pipe respectively cable.r bzw. Kabel eingeschlagen.

The pressure load of 3 bar against gas and water is safely achieved. The use in a wall sleeve is also possible.

Certificates

To offer our customers the best possible quality and service, we are organized according to DIN EN ISO 9001:2015 and have this continuously checked and certified.

CERTIFICATE ISO 9001:2015

This certification documents our conformity of the quality management system

AEO-CERTIFICATE

Authorized Economic Operator "AEOC (customs simplification)

PlugiT SEALING PLUG

- Lloyd's Register: Pressure test (3 bar)