Pipe and cable penetration for hydrostatic sealing and

optimal in combination with an annular space seal

PipeX

Wall Sleeve

Type selection

PipeX FZH - closed

PipeX FZH - split

Fields of application

This wall sleeve can either be set in concrete, bricked in or installed watertight in a wall opening with mortar. The circumferential grooves lead to a watertight bond with the building. For use in concrete basins or tanks, wall sleeve can be backed with a coating of the concrete construction.

Material

Asbestos-free fiber cement; consisting of cement and glass fibers; color light gray

Properties

External groove circumferential not spiral; coatable

Sizes

ND 80 to 800; lengths: 200 to 1200 mm

PipeX Steel - galvanized

PipeX Stainless Steel - V2A

Fields of application

For pipe and cable penetration for embedding in concrete or insertion in the concrete formwork

Material

Galvanized steel; stainless steel V2A (1.4301) V4A (1.4571);

coating and sanding according to the length of the wall thickness

Properties

Standard sleeve supplied with a welded-on anchor flange acting as an annular water-stop plate.

Sizes

On request

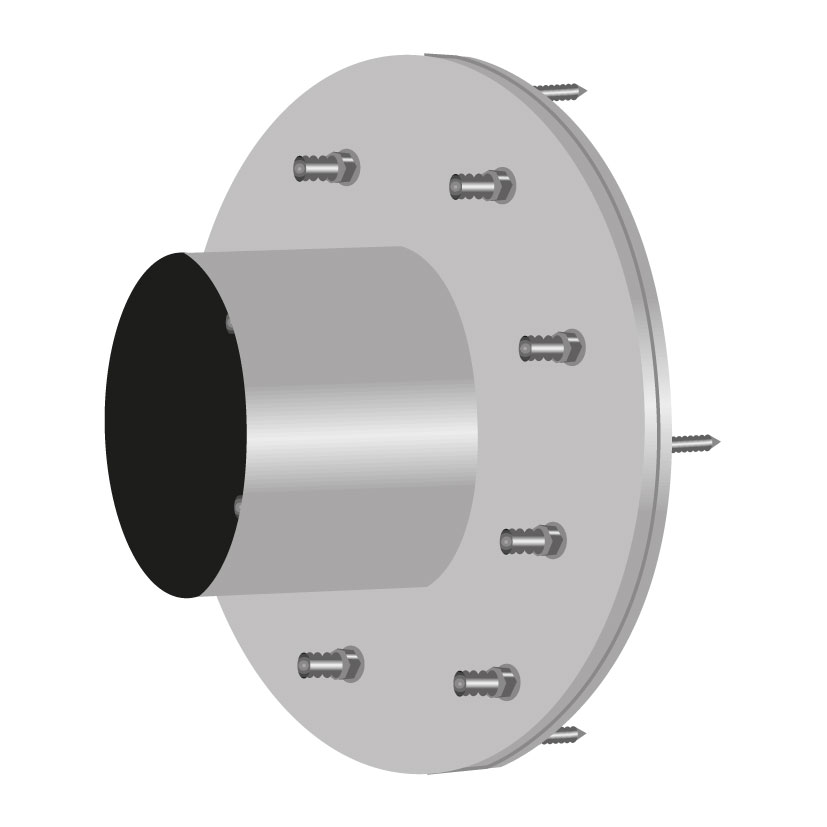

PipeX MFL - galvanized

PipeX MFL - stainless steel

Fields of application

For pipe and cable penetration in accordance with DIN 18533; for buildings with sealing sheets (black tube); wall sleeve with fixed / loose flange for installation in the concrete formwork

Material

galvanized steel; stainless steel V2A (1.4301) V4A (1.4571)

Properties

Anchoring via concrete anchors or cap nuts; version available for retrofitting installation by means of dowels; against pressing and non-pressing water

Sizes

From ND 80 to ND 1000 (sleeve diameter)

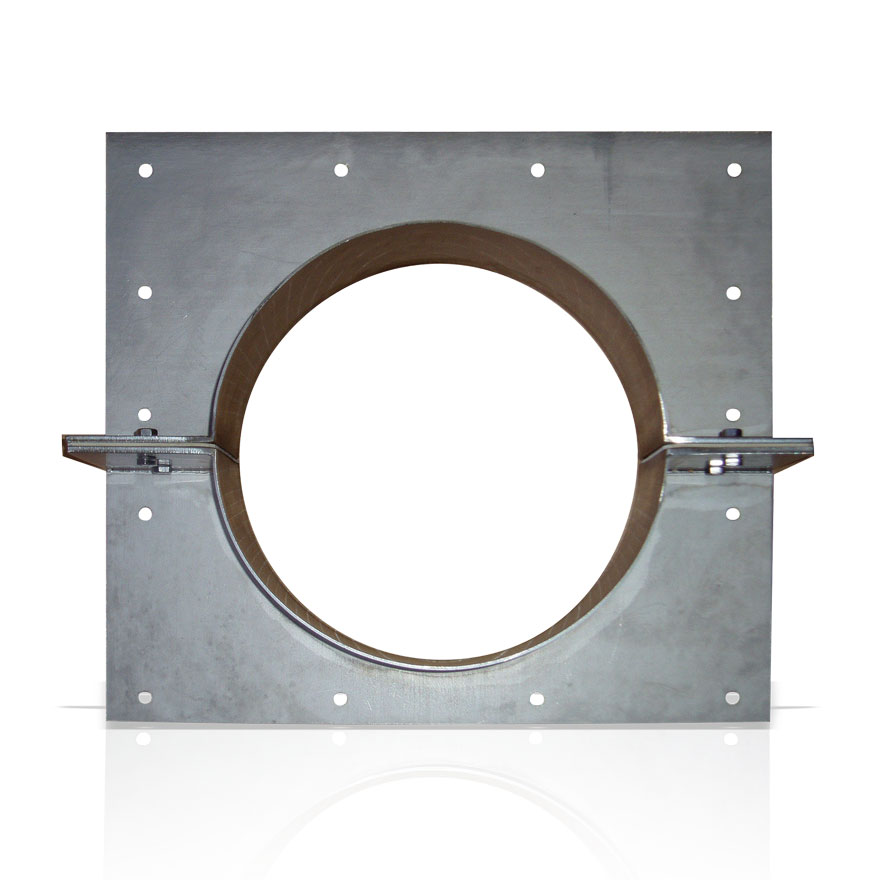

PipeX V - closed

PipeX V - split

Fields of application

For pipe and cable penetration for buildings without sealing sheets (white tub); prefabricated wall sleeve for installation in front of the wall

Material

galvanized steel; stainless steel V2A (1.4301) V4A (1.4571)

Properties

Easy installation with sealing adhesive and dowels

Sizes

From ND 80 to ND 1000 (sleeve diameter);

other sizes on request

PipeX VFL - galvanized

PipeX VFL - stainless steel

Fields of application

For pipe and cable penetration in accordance with DIN 18533; for buildings with waterproofing sheets (black tub); prefabricated wall sleeve for installation in front of the wall

Material

Galvanized steel; stainless steel V2A (1.4301) V4A (1.4571)

Properties

Against pressing and non-pressing water

Sizes

From ND 80 to ND 1000 (sleeve diameter);

other sizes on request

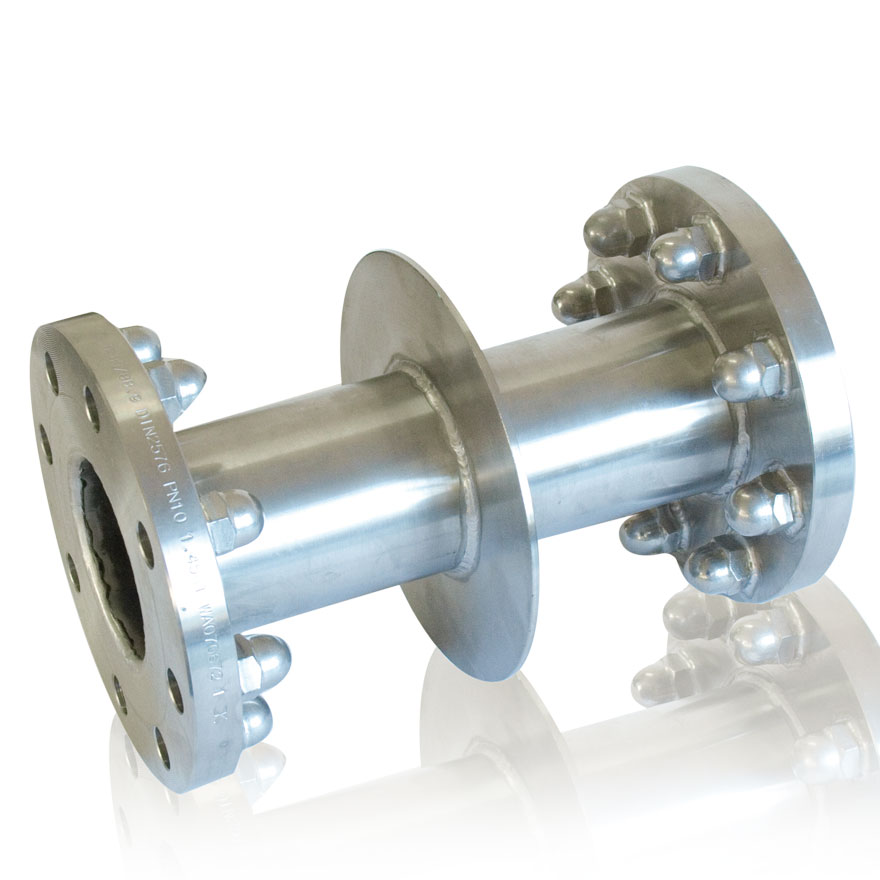

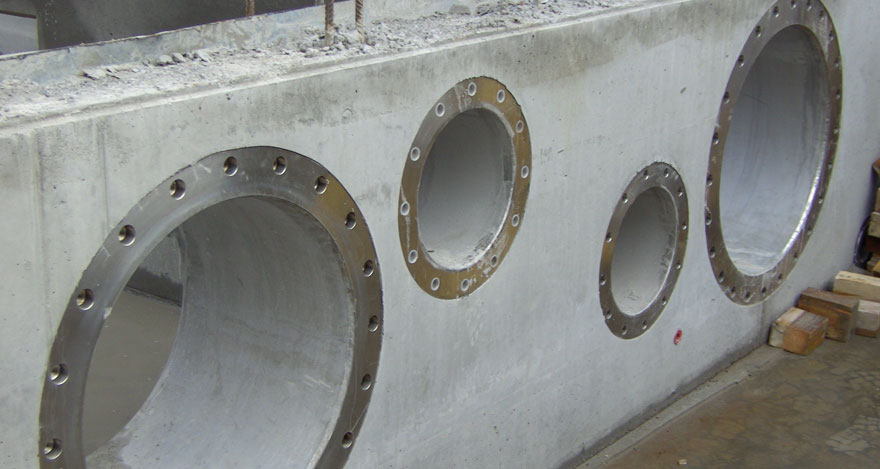

PipeX FF

Fields of application

Stainless steel wall penetration in the field of waterworks, sewage treatment plants and industrial sector

Material

Stainless steel V2A (1.4301) or V4A (1.4571)

Properties

Connecting flanges with tightly back-welded cap nuts;

welded-on wall collar

Sizes

ND 50 to 500

Download

Product Information

PipeX FZH

Properties

- water pressure-tight

- high dimensional accuracy

- smooth inner wall

- good bonding to concrete

- high stability

- non-flammable

Fields of application

For wall, ceiling and floor penetrations, fiber cement wall sleeves are used for hydrostatic sealing of pipes

Description

In combination with a seal that covers the annular space, a suitable pressure-tight sealing is guaranteed between the wall sleeve and the carrier pipe.

Notes

For split version of PipeX FZH additional putty is necessary. Available as a set with bar spacers in 2,5 kg/container. The consumption is approx. 125 g per 100 mm sleeve length.

PipeX On Wall-Face Sleeve

Properties

- black/white tub

- split/closed

- galvanized/stainless steel

Fields of application

• clean surface for for sealing of pipe and wall penetrations, going through walls and ceilings

Description

For constructions with sealing sheets, wall sleeves or prefabricated wall sleeves with fixed/ loose flanges are required to be in accordance with DIN 18533. Differentiation based on pressing and non-pressing water. Long lasting solution for all wall penetrations.

The PipeX Steel Wall Sleeves are made of welded or seamless steel pipes and are protected against corrosion by galvanizing. Also available further corrosion protection measures on request.

Notes

- for white tubs we recommend on wall-face sleeves

- bolt connection for fixed/loose flanges are part of the delivery.

- suitable inlays (2 rubber sheets)

Technical Information

PipeX MFL: Wall Sleeve with fixed and loose flange

according to DIN 18533, steel parts galvanized, alternatively stainless steel

PipeX VFL: On Wall-Face Sleeve with fixed and loose flange

according to DIN 18533, galvanized, alternatively stainless steel

PipeX V: PipeX V: On Wall-Face Sleeve closed and split version

galvanized, alternatively stainless steel

PipeX FZH

Important notes on installation

- only cut wet fiber cement.

- use only hand-operated or slow-moving equipment with a dust collector.

- impact of the concrete from a great height or with high pressure directly on the component is to be avoided during concreting.

- when placing the sleeves in the formwork, ensure enough concrete cover (min. 100 mm circumferential around OD sleeve depending on static specifications, concrete quality and compaction).

- for the formwork, the minimum distances according to the structural analysis must be observed.

- carry out a visual inspection for damage before installation.

- please observe the valid Federal Ordinance on Hazardous Substances.

- process only outdoors or in well-ventilated areas.

- the fine dust endangers health when inhaled, wear a dust mask.

PipeX FF

The stainless steel wall penetration is cast in the concrete wall. It provides a seal against a range of media. The carrier pipes are flanged directly to the cast-in penetration.

The PipeX FF installation is carried out flush with the casing for a variety of applications such as sedimentation tanks, high-level tanks, shaft constructions etc. The flanges can be manufactured as welding neck flanges

according to DIN 2632 (PN10) or smooth flanges (turned on all sides with reduced sheet thickness) similar to DIN 2576 (PN10).

The stainless steel pipes used correspond to the ISO pipe range. 1. The PipeX FF is supplied with wall flange welded on the middle, an annular water stop plate that guarantees safe sealing of the sleeve outer diameter and also serves as a wall anchor. The PipeX FF is manufactured in S304 (V2A) (1.4301 or1.4541) or S316 (V4A) (1.4571), other materials upon request. It is welded in inert gas and stained and passivated afterwards. On request PipeX FF can be supplied sanded, without wallflange or with only one flange sheet (F-piece).

Other pressure stages available upon request. All connecting flanges have capnuts welded tightly on the back.

Suitable Accessories

Certificates

To offer our customers the best possible quality and service, we are organized according to DIN EN ISO 9001:2015 and have this continuously checked and certified.

CERTIFICATE ISO 9001:2015

This certification documents our conformity of the quality management system.

AEO-CERTIFICATE

Authorized Economic Operator "AEOC (customs simplification)"

Wall Sleeves

- PipeX FZH - MFPA Leipzig: Pressure-tight when installed

- PipeX FZH - MFPA Leipzig: Classification report fire behavior A1 - DIN EN 13501-1

- FHRK quality seal for PipeX FZH: FHRK test specification GE-102