Pressure-tight Dynamic Wall Seals

made of high-quality Rottolin

RottoX

Dynamic Seal

Type selection

RottoX VDW® - radial/axial movement

Fields of application

The flexible sleeve is the ideal compensator for radial and axial movements. Particularly suitable for pre-insulated pipe wall penetrations and for constructions without sealing sheeting.

Material

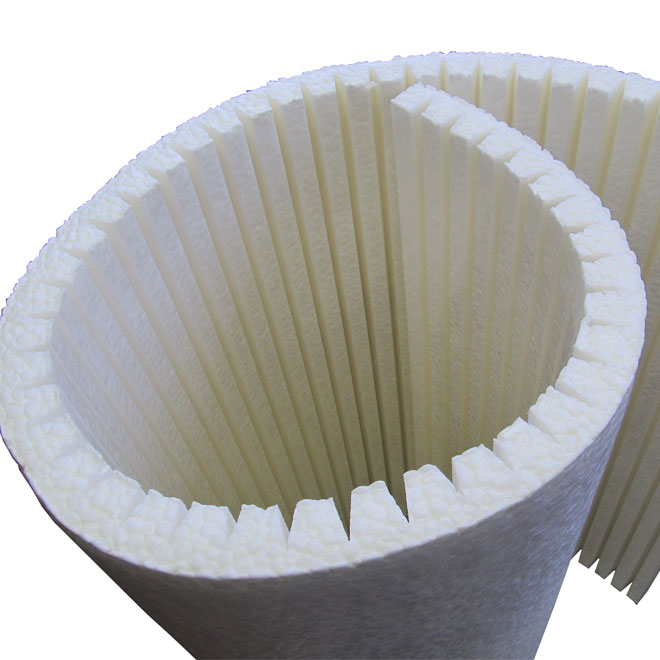

High-quality Rottolin; seamlessly manufactured; permanently elastic sealing compound; anchor dowels; pressure plate V2A

Properties

Material thickness approx. 6-8 mm; Color red; Shore A 50° ±5; tensile strength 11 N/mm2; elongation at break 400%; tear strength; 27 N/mm2; max. continuous operating temperature 55 °C; weldable (only split version); tight against pressing water up to 1.0 bar

Sizes

Core drillings from 150 to 1000 mm

RottoX VDW® OD - flexibel

Fields of application

The flexible sleeve made of high quality Rottolin can compensate pipe bendings, and is suitable for non-moving pipes penetrating buildings without sealing sheet

Material

High-quality Rottolin; seamlessly manufactured; permanently elastic sealing compound; anchor dowel; pressure plate V2A

Properties

Material thickness approx. 6-8 mm; color red; Shore A 50° ±5; tensile strength 11 N/mm2; elongation at break 400%; tear strength; 27 N/mm2; max. continuous operating temperature 55 °C; pipe bending up to 20 °C; tight against pressing water up to 1.0 bar; weldable (only split version)

Sizes

Core drillings from 150 to 900 mm

RottoX Temp - radial/axial movement

Fields of application

The RottoX Temp end seals for pre-insulated pipes are specially developed to provide a pressure-tight seal between carrier and casing pipes.

Material

High-quality Rottolin; seamlessly manufactured; stainless steel fastening straps

Properties

Material thickness approx. 9-11 mm; color red; Shore A 50° ±5; tensile strength 11 N/mm2; elongation at break 400%; tear strength; 27 N/mm2; max. continuous operating temperature 55 °C; weldable (only split version)

Sizes

Dimensions 50 x 125 mm up to 1100 x 1200 mm

Download

Product Information

Properties RottoX VDW®

- Supports axial and radial load changes up to +/-25 mm

- Compensates pipe settlements, depending on pipe OD and core hole size up to 40 mm

Properties RottoX VDW® OD

- Pipe bending up to 20°

Properties RottoX Temp

- Due to their high flexibility, the casing end seal allows axial and radial movements between casing and carrier pipe.

Fields of application

- Sleeve for sealing pre-insulated pipes or other moving pipes for wall penetrations.

Description

Due to the unique manufacturing process, the seamless production is possible for nearly all pipe combinations and sizes. Installation is very easy due to the pre-formed sleeves. As a result of seamless production, without punched openings, subsequent tensions will not cause cracks.

Even the weld seam of the split version has the same properties in the base material, it is hot-plate-welded without any additional materials. This could be carried out on site by our partner.

The material Rottolin is also characterized by high durability and flexibility. This is particularly important, for example, when used in acidic soils. Of course, this also applies to the standard STM sleeve for installation on a carrier pipe / casing pipe combination.

Notes

- For installation in the ground, the sleeve must be covered with an expansion pad, to reduce the pressure of the soil on the sleeve, so that a moving during the backfilling process is still possible.

- To ensure tightness of RottoX Temp, the annular space should not be larger than 70 mm

Technical Information

RottoX VDW®

Penetration through the wall "Compensating Wall Seal"

- With a flush connection to the dynamic end seal one layer of expansion pads is wrapped around the carrier pipe. (Width of the expansion pad min. 50 cm). By means of adhesive tape, fastening straps, cable ties etc. it must be fixed proper to the pipe, so that a moving or opening of the expansion pad layer is not possible during the backfilling process.

- Another layer is applied to the expansion pad after step 1. The width is chosen so that the expansion pad butts against the casing end seal and is flush with the previous layer.

- Step 2 needs to be repeated (layer by layer) until the top layer of the expansion pad is flush with the wall -covering the dynamic end seal. Finally, one more layer of expansion pads is wrapped and fixed over the entire installation

Suitable Accessories

Certificates

To offer our customers the best possible quality and service, we are organized according to DIN EN ISO 9001:2015 and have this continuously checked and certified.

CERTIFICATE ISO 9001:2015

This certification documents our conformity of the quality management system.

AEO-CERTIFICATE

Authorized Economic Operator "AEOC (customs simplification)"

Certificates

RottoX Dynamic Wall Seal

- VDW® - MFPA Leipzig: Pressure-tight when installed

- RottoX Temp - MFPA Leipzig: Pressure-tight when installed