Individual solutions for pull-in of carrier

pipes into casing pipes or tunnels

CaseX

Steel Spacer/Roller Ring

Type selection

CaseX Steel Spacer

Fields of application

For pipe pull-in and pipe positioning where the requirements exceed the possibilities of a DSI® casing spacer

Material

Half shells and skids are made of steel; surfaces are optionally raw (black) without corrosion protection or bitumen-coated, plastic-coated, galvanized or in stainless steel (V2A/V4A); sliding bodies made of PP, steel, brass, PTFE etc.; screws made of galvanized, high-strength steel or stainless steel

Properties

Individual solution according to customer requirements; high temperature resistance and load capacity, as well as adjustment to large annular spaces

Sizes

According to customer requirements

CaseX Steel Roller Ring

Fields of application

For pipe pull-in and pipe positioning where the requirements exceed the possibilities of a DSI® casing spacer.

Material

Half shells and skids are made of steel; surfaces are optionally raw (black) without corrosion protection or bitumen-coated, plastic-coated, galvanized or in stainless steel (V2A/V4A); wheels made of polyamide, steel or stainless steel; screws made of galvanized, high-strength steel or stainless steel

Properties

Individual solution according to customer requirements; high temperature resistance and load capacity, as well as adjustment to large annular spaces; reduced pull-in friction resistance

Sizes

According to customer requirements

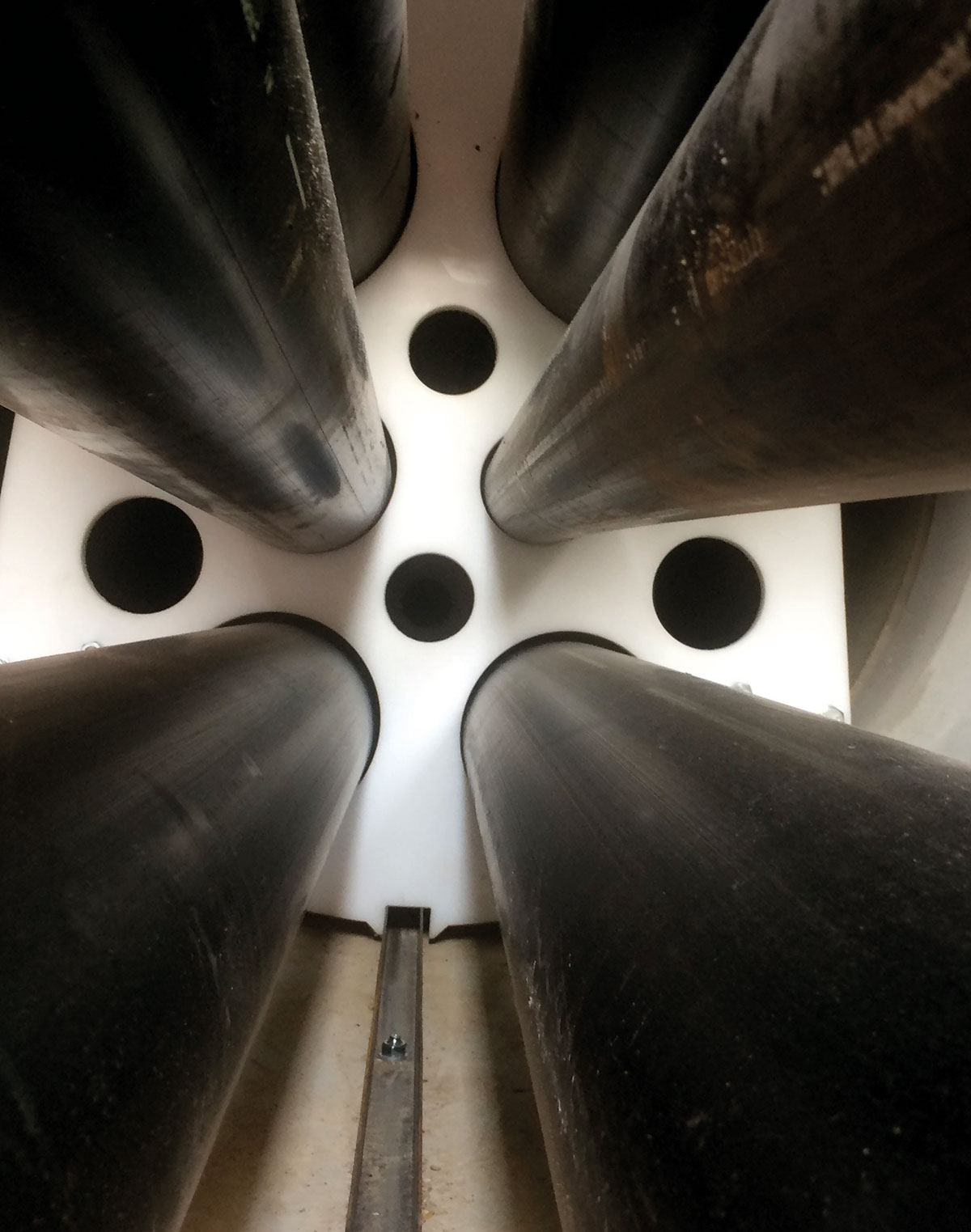

KuRRi® Polymer Roller Ring

Fields of application

Pipe pull-in and pipe positioning; pull-in of multiple pipes such as pipe bundling; individual solution according to customer requirements, where the requirements exceed the possibilities of a Ranger® II casing spacer

Material

Polyamide wheels with bolted steel axle (stainless steel on request); polyethylene plate with appropriate holes for the carrier pipes;

Properties

Pull-in with low tensile forces by means wheels arranged in star-shape; weight approx. 5-7 kg/ring; individual solution according to customer requirements

Sizes

According to customer requirements

Download

Product Information

CaseX Steel Spacer/Roller Ring

Properties

- Easy pipe installation by reducing friction between the carrier pipe and the casing pipe

- Provide support for the carrier pipe

- Act as spacers between carrier pipe and casing pipe.

The carrier pipe can be placed in concetric or eccentric positions in casing pipe - Ensure electrical isolation between carrier pipe(s) and casing pipe

Fields of application

Often it is not possible to lay pipes in open ditches. For example, for rail or raod crossings it is first necessary to drive casings underground.

By using steel spacers or roller rings the carrier pipe can be inserted into the casing pipe.

Description

Each ring consists of two half-shells, which are clamped together by hexagonal bolts and nuts. The CaseX steel spacers/roller rings are manufactured individually.

Notes

- Different skid heights for the upper and lower half shells allow any position of the carrier pipe in the outer casing. For longer distances, if necessary with guide rail (anti-twist device).

KuRRi® Polymer Roller Ring

Properties

- The basic disc is made of polyethylene with corresponding drill holes and gaps for carrier pipes.

The drill holes are slightly bigger than the outside diameter of the respective carrier pipes - Possible additional openings (as required), which facilitate a better flow of filling material

- Wheels made of Polyamide with bolted steel axle (stainless steel on request)

- Connection of various polymer roller rings to each other with pull rods

- Guide rail to prevent twisting (if necessary) which will be fixed in casing pipe by customer. The working space in the tunnels, galleries or pipe penetrations must be sufficient according to german standard DGUV

Description

In case of socket connections of the carrier pipes (e.g. electrofusion sockets), the sockets can be placed so they are in contact with the polymer roller ring (depending on available space). This prevents axial displacements of the carrier pipes in the feedthrough direction.

Notes

- If a steel winch is required for longer lengths, it can be easily fixed on the pull rods without the use of special tools

Fields of application

The polymer roller rings are suitable for the insertion of several cable pipes in relation to plastic pipelines in the field of electricity, gas and water supply.

Technical Information

Steel roller ring with holding clamp for socket joints

This steel roller ring also has two (or more) clamps. The additional clamps are located on the main holding

clamp.

Individual steel solutions

In the wide field of protective pipe laying, there are applications where plastic spacers and KuRRi can no longer meet the requirements

Examples:

- Multiple pipes in exact defined position

- Support for long distances

- Permanent pipe movement

- High temperature

- Heavy weight

- Integrated tensile protection

- Hanging constructions

Application example

Certificates

To offer our customers the best possible quality and service, we are organized according to DIN EN ISO 9001:2015 and have this continuously checked and certified.

CERTIFICATE ISO 9001:2015

This certification documents our conformity of the quality management system.

AEO-CERTIFICATE

Authorized Economic Operator "AEOC (customs simplification)"